gearbox cvt Fundamentals Explained

gearbox cvt Fundamentals Explained

Blog Article

CVTs could use hydraulic strain, centrifugal power or spring stress to produce the force essential to alter the pulley halves.

Trigger: Rattling noises can arise as a consequence of loose or broken parts throughout the transmission or perhaps the encompassing elements. This might be a thing so simple as a unfastened warmth defend or a far more major situation within the CVT.

Due to the fact there isn't any tough equipment shifts, the CVT permits you to enjoy clean driving and acceleration at any speed, as CarFax points out. Additionally, it eradicates sudden downshifting after you’re looking to get extra electric power to move within the highway.

This would make the CVT much more adaptable than its regular counterparts, enabling a clean ride and easy acceleration Inspite of varying street disorders.

Adhering to some maintenance schedule can significantly extend the life within your CVT and guarantee its overall performance continues to be regular.

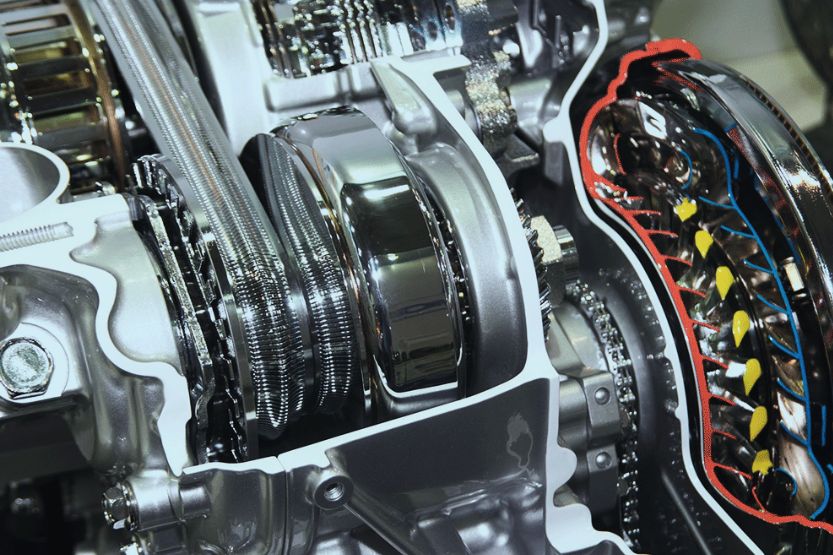

You will find there's 2nd, much less commons form of CVT that utilizes a number of discs and rollers, however it operates on very similar ideas. CVT and common transmission electrical power motor vehicles are marginally distinctive.

If the two cones with the pulley are considerably aside (in the event the diameter improves), the belt rides lower in the groove, and also the radius from the belt loop going across the pulley gets smaller sized. When click here the cones are close together (when the diameter decreases), the belt rides higher in the groove, and the radius of your belt loop likely within the pulley receives more substantial.

Whilst CVT has recently gained popularity, with new innovations offering greater performance, the look has existed for hundreds of years.

The travel ratio is usually established to infinity (i.e. a stationary output disk) by moving the output disk to the center in the enter disk. The output course will also be reversed by moving the output disk past the center in the input disk. The transmission on early Plymouth locomotives worked in this way, although on tractors utilizing friction disks, the selection of reverse speeds was usually limited.[28]

Contrary to regular automated transmissions, continually variable transmissions don't have a gearbox having a established range of gears, meaning they do not have interlocking toothed wheels.

It's not a coincidence. Most CVTs are certainly not nevertheless able to handling high-torque purposes without the need of shattering by themselves into a thousand oily bottlecaps.

Bigger Costs: Upkeep and repair service prices for CVTs may be increased than for regular transmissions due to the specialized elements and know-how associated.

Maintenance explains. Constantly variable transmissions can not take care of the greater horsepower, Which is the reason they don't seem to be used on sports coupes and overall performance vehicles.

The technological storage or obtain is necessary to build consumer profiles to send out advertising and marketing, or to trace the consumer on an internet site or across many Sites for related advertising and marketing needs.